You are currently using an outdated browser.

Please consider using a modern browser such as one listed below:

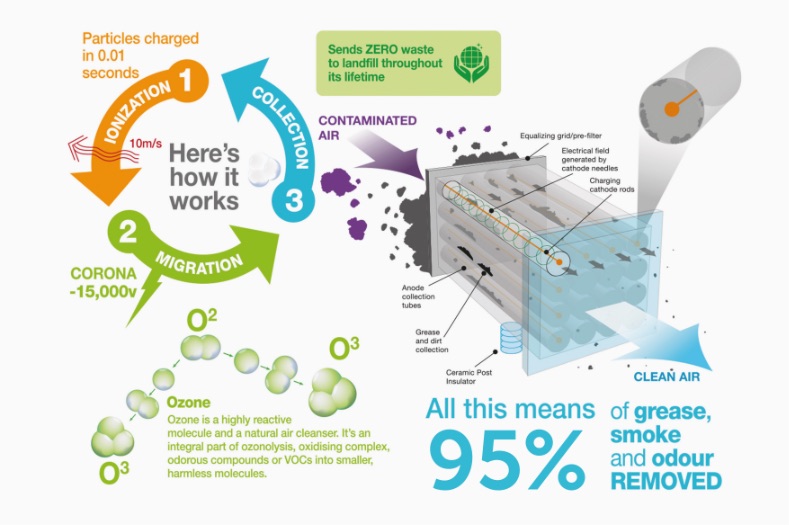

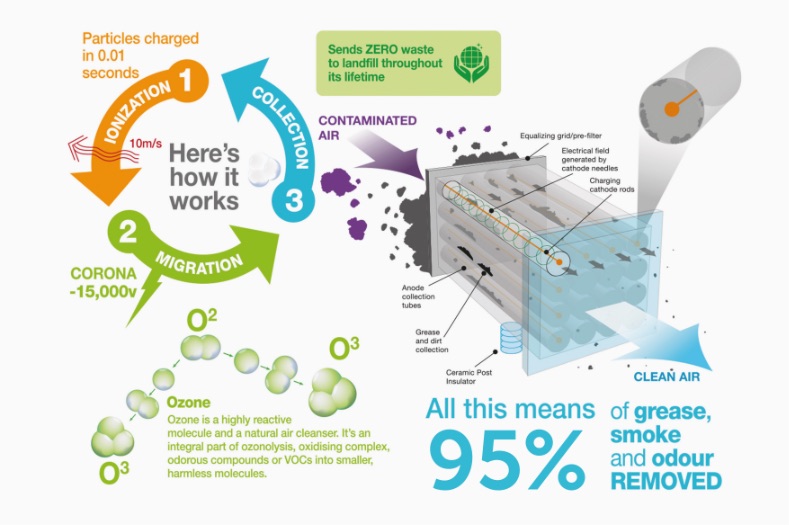

Maximum efficiency, minimum space: Chapman Ventilation’s Electrostatic Precipitator (ESP) is the most sustainable and efficient way of removing grease and smoke from kitchen emissions.

It’s simple – an ESP provides the highest level of efficiency available today. Up to 95%, in fact. Gone are the days of costly, space-consuming and non-recyclable filters that send tons of waste to landfill every year. Instead, electrostatic precipitation offers a truly sustainable and lowmaintenance option. It uses an electrostatic charge targeted specifically at grease and smoke particles to remove these contaminants from the air stream, causing them to form a film inside the ESP unit.

Chapman Ventilation specialises in creating bespoke integrated solutions. That’s why our robust ESP units can be configured to accommodate any air flow, and provide unrivalled filtration of grease and odours.

The cathode needles are positioned centrally within the cylindrical anode collectors. This ensures a constant, robust and improved ionisation field.

A flow-equalisation plate removes large particles and encourages even air-flow distribution across the cells, thereby increasing efficiency.

Our systems now generate ozone to help reduce odours from kitchen emissions.

Typically, existing ESP technology only allows for an inlet velocity of 3-4 m/s. Chapman Ventilation’s ESP can handle three times that. Our unites are able to handle velocities up to 10 m/s with no detrimental effect on performance.

We have solved one of the major problems consistent across all ESPs until now: the need to swap out cells as part of a monthly cleaning cycle. We have developed a technique that allows us to clean cells on site there and then, without having to remove and replace them.

Patented technology varies power delivery, ensuring efficient particulate removal.

You are currently using an outdated browser.

Please consider using a modern browser such as one listed below: